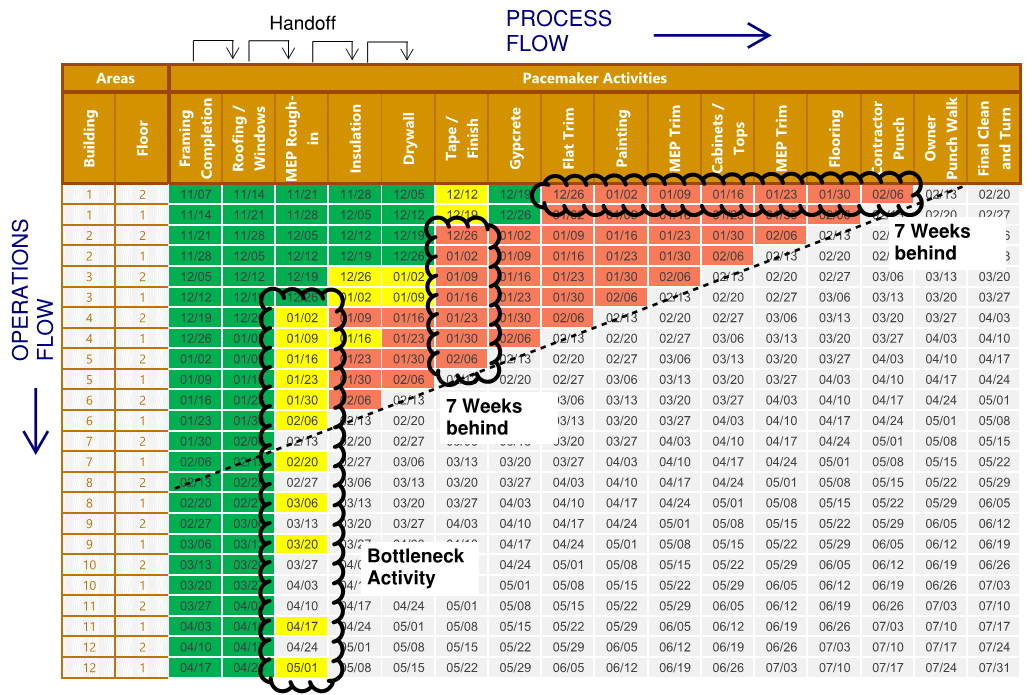

Case Study

MULTIFAMILY HOUSING

Challenge

A complex and difficult to read 38-page schedule left an apartment construction project delayed and out of control.

Results

The Clear Flow Matrix condensed the entire schedule down to one page of information and quickly highlighted bottlenecks.

This case study describes a project entailing 12 wood-framed 2-story apartment buildings. This project was several months behind schedule, and progress wasn’t sufficient to meet the originally scheduled completion date. The project was effectively out of control.

For this reason, the owner of the project requested that Lott Brothers Construction Company (LBCC) provide consultation regarding the project progress and schedule completion status. The original technique used for scheduling and production control on the project was a CPM network-based Gantt Bar-Chart depicting scheduled activities in detail for each of the buildings. The resulting schedule was presented in 38 letter-sized pages of Gantt chart schedule information.

LBCC staff reviewed the current completion status of each building and input the data into a Clear Flow Matrix production control plan to establish a projected date for completion. The outcome of this effort was a single page of information representing the completion schedule for the entire project, beginning with framing.

This example use highlights the ease with which managers can use Clear Flow Matrix to identify not only delays, bottlenecks, and trades responsible for delays, but also the appropriate trades and location-areas required for steady acceleration as bottlenecks are alleviated. The status of work completed on the project indicates clearly the poor results that occur when projects do not focus attention on both axes of project flow (process flow and operations flow) on a frequent basis.

At this multifamily residential project, the first two trades on the project accelerated their work, partially completed their location-area activities ahead of schedule, and then effectively left the project. However, even with the supposed high operations efficiency of these two trades, the project was still delayed because of bottlenecks that developed later. Re-entrant work was required to finish incomplete work done by the supposedly efficient trades now departed from the project.

This situation highlights the need for a balance between trade operations (operations flow) and handoff process (process flow). The Clear Flow Matrix schedule prepared for this project was employed by LBCC and the client to eliminate the bottlenecks and smoothly accelerate completion of the project.