Calling All Trade Partners

What’s The Situation?

As we all know, taking the time necessary for smoother handoffs with smaller crews can be a challenge for trade partners looking to get ahead and stay there. It seems logical, right?… get as much done as you can so you can maximize your time and money – and all while optimizing your contribution towards the completion of the job. But what if we told you there’s a better way?

How Did We Get Here?

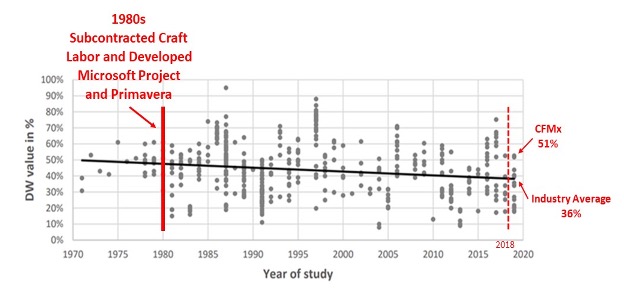

Since the 1980s, the responsibility of trade partners to manage company cashflow and profitability on multiple projects, with multiple general contractors, has forced them to balance the needs of any individual project with many other balls in the air. The problem, however, is that managing their company workflow often comes at the expense of the process and operations flow – not to mention the direct work percentage.

What’s The Catalyst for Change?

Then we have the CPM and multi-page Gantt charts that have become the standard for project management and are always too detailed to present phase planning in terms of flow (especially Shingo’s two flows). In a typical scenario, discussions go from milestone dates to phase start dates, and then down to daily activities aimed to justify the projected completion dates.

The challenge with this is easy to see. When the 30 plus pages are discussed with the trade partners, the response to planning crew sizes and start dates immediately defaults to a very firm “wait and see.” Why? The amount of detail is overwhelming and the path to progress becomes less obvious.

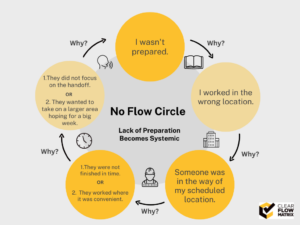

The result? The No Flow Circle begins again as trade partners balance the work areas available with their own manpower projections against the uncertainty that other trade partners will complete the area they are currently occupying. A reinforced wait and see attitude is then justified in the weekly project meetings by aggressively pointing out all the conflicts and delays preventing them from moving forward. Then, to protect the efficiency of their workforce, the trade partner demands a larger work area to buffer for further delays from other trade partners.

See where we’re going here? Each week, the superintendent and trade partners collide as the No Flow Circle swirls and consumes the entire project team – sacrificing both time and money as the schedule dates become more and more unmanageable.

How Can We Do This Better?

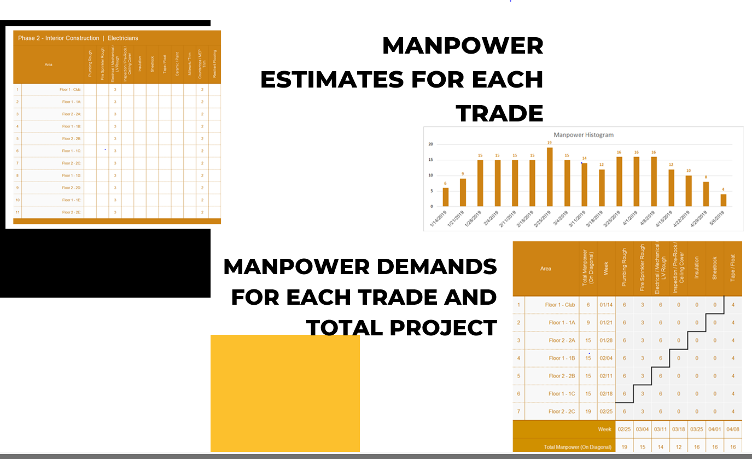

Okay, we know that in the midst of the No Flow Circle it’s almost impossible to visualize a discussion of manpower projections – especially when the first step typically requires someone to cherry pick through 30 pages of seemingly unnecessary detail. We get it and it would be unrealistic to expect it. So, we came up with a better way!

Manpower should be planned based on flow from the earliest phase planning efforts so that decisions can be reflected as planning progresses – placing an emphasis on flow proactively, at the beginning of project, versus reactively, after the No Flow Circle has already commenced.

Let Clear Flow Matrix Do It for You!

With the Clear Flow Matrix, trade partners are able to visualize how smaller crews can move from area to area and increase productivity by decreasing the variance caused by larger crews moving in for short-term catchup efforts. So, the capacity to retain smaller crews for longer durations means each individual man is producing more completed product per manhour.

Translation: Steady Manpower = Increased Profits!

With the help of Clear Flow Matrix, trade partners can both establish and maintain a focus on manpower, resulting in smaller crews and smaller handoffs, which ultimately leads to a substantial reduction in variance. And this reduction in variance increases productivity and decreases labor cost, both of which result in noticeable savings!

Interested?

Get Started for FREE!

Recent Comments