Calling All Construction Engineers to

Know what you are building before you start!

Welcome back to our blog series: A Day in The Life. Today, we’ll be discussing the steppingstones and stumbling blocks commonly faced by construction engineers out there at any given jobsite. We’ll discuss how to maximize efficiencies and minimize bottlenecks – both resulting in the success of your project.

You don’t know what you don’t know!

Construction engineers are not trade supervisors, nor assistant project managers, nor assistant superintendents; they are engineers who have been taught to identify problems before they occur. They learn to identify the specific problem and break it down into smaller more manageable parts, which always include diagrams of physical or theoretical relationships of the problem parts. This training and aptitude have defined engineers for centuries, but in construction these skills are often ignored. Engineering assignments are often clerical and assistant roles until they gain experience. This is necessary and appropriate initially but then the function of construction engineering is often forgotten. Instead of looking for problems before they happen, by working out solutions to what they don’t know, they become firemen putting out the emergency of the day.

The construction engineering function is where processes collide!

Design processes do not start from the bottom up. They must first address use and purpose. General contractors must also deal with budget and constructability issues before getting into the dimensional details, while trade partners each have their own processes centered around equipment, material quantities, and accessibility constraints. With the development of so many improved construction products and advancements in CAD processes, design offices have come to depend more and more on the submittal process to complete the detailing of project design. At the same time, General Contractors depend increasingly on Trade Partners to furnish and complete detailing of their respective trades. In the past decades the strategy for managing this collision has been to break the processes into smaller and smaller pieces and insert them into an all-encompassing network schedule and force everything to mesh and sync together.

More detailed scheduling does not produce better handoffs!

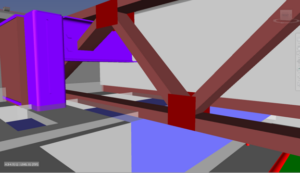

The detailing of projects cannot be accomplished by more complex scheduling, design and construction details must be completed before installation and used to communicate sequential and dimensional requirements. The submittal process should result in actual overlays of vendor drawings and design documents to assist installation and avoid conflicts. BIM conflict resolution is a great help with physical conflicts, but the efforts of the construction engineer also include detailed drawings of the installation of materials and finishes primarily focused on the handoff between trades.

With the Clear Flow Matrix, by focusing on balancing production, the construction engineer can accomplish the same detailed schedule information in 1/10 of the time, re-allocating that effort to resolving bottlenecks.

Matrix image process and operations

With Clear Flow Matrix, the balanced production front starts smaller crews earlier and encourages more timely completion of the submittal functions to meet earlier start of smaller areas. Balancing process flow and operations flow on a construction site requires all area handoffs to be balanced with the trade production. This is where the construction engineer’s efforts really start to make a difference.

As areas and scope of work for each trade partner, for each handoff, are identified, they must be communicated on drawings and diagrams that are easy to read and understandable for the whole site team.

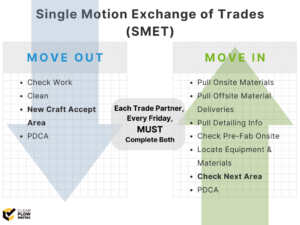

Smet handoffs graphic

Each trade operation must be identified with and balanced to the area handoff and site location, as well as visually communicated to identify each specific trade operation and ensure a successful handoff. Superintendents and trade partners can then have meaningful and accurate discussions, and communication is re-established around flow or (as we like to say) production rates versus schedule dates.

What does this mean for the construction engineer?

Utilizing the balanced production front in the Clear Flow Matrix, construction engineers can identify and resolve bottlenecks ahead of production, avoiding the No Flow Circle altogether!

Recent Comments