Meet Your Hero: Herbie

Welcome to our next blog series: A Day in The Life. Here, we’ll be discussing the steppingstones and stumbling blocks that come with the various trade positions out there in any given jobsite. We’ll discuss how to maximize efficiencies and minimize bottlenecks – both helping you succeed.

Circling Back

As you know, we’ve already talked in our last blog about the challenges that come with keeping pace when the No Flow Circle rears its circumference. Communication breakdowns become systemic as trade partners work to stay one step ahead of the next trade, delivery, or RFI – only to provide yet another excuse for why time keeps slipping away. We also know the answer to reestablishing flow: The balanced production front used in CFMx, which provides the tool for managing production rates versus schedule dates, consequently restoring order and balance to your jobsite.

Meet our Superintendent, Herbie! Herbie once made the costly mistake of not training his team and trade supervisors on balancing production, trying instead to assume a position in the middle of the circle. Whose Herbie?

Why would he do such a thing? Because, to Herbie, it seemed like the most obvious way to break excuses and point trades back to their production at hand.

How did it work out? Herbie almost immediately realized that instead of becoming the solution (his intended result), he quickly became the bottleneck!

What foiled Herbie’s plan? As is evident in the Theory of Constraints, the superintendent may see some short-lived improvement in transitioning to the middle of the circle but will soon be overloaded as trade partners allow him to assume an impossible role of managing everyone’s priorities.

What’s the solution? Only when all trade partners assume their roles and responsibilities can production be balanced through efficient trade handoffs that maintain and establish the balanced production front.

The result? Meet your hero, Herbie!

Photo Citation: The Goal: A Business Graphic Novel 2017 Goldratt, Ltd. And The North River Press Publishing Corporation

Flow Is Optimized

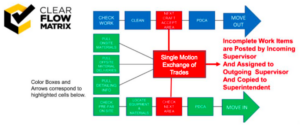

As Herbie implements the flow provided by the CFMX, each trade partner begins to understand their responsibilities for maintaining the balanced production front and Herbie can then begin to unpack his backpack – distributing responsibilities evenly to the crafts and other members of the project team. Methods such as Pull Planning and Last Planner System (LPS) are essential to improving overall communication and collaboration during this phase. And when communicated, tasks set during the Weekly Work Planning allow teams to agree to activities required to meet the pace for weekly handoffs. Within the framework of CFMx, these commitments are optimized sustainably to ensure the project continues to flow and bottlenecks stay at bay. Balanced flow can then be brought back to the project and maintained along the balanced production front, as trade partners and project teams focus on the Single Motion Exchange of Trade (SMET) each week.

Using SMET, the handoffs are identified along the balanced production front and confusion is minimized. Materials can be more easily obtained, and equipment is scheduled to ensure nothing is held up looking for or ordering materials at the last minute.

Balance Is Restored

As we can see, managing the handoffs is the most crucial part of maintaining balanced flow. Each handoff must be identified, exploited, and subordinated or they will each become a bottleneck of their own. Last Planner and all task management tools and software can be an enormous benefit in their effectiveness – all of which is optimized substantially by using CFMx and the balanced production front.

Recent Comments